lignoloc® Wooden Nails

Building sustainably – nail by nail

LIGNOLOC® is the first collated nailing system made from the renewable raw material beech wood, perfectly combining performance and sustainability. Ideal for all timber construction companies aiming to realize their projects in a circular, metal-free, and highly efficient way.

With LIGNOLOC® wooden nails, we have completely rethought fastening technology – taking a sustainable, traditional fastening method and advancing it to meet today’s requirements.

LIGNOLOC®, the world’s first shootable wooden nail, is setting new standards for the future of construction in terms of sustainability and efficiency. It is ideally suited for industrial production as well as ecological woodworking. With the specially developed FASCO® pneumatic nailer of the LIGNOLOC® edition, the wooden nails can be driven into solid wood and engineered wood products with ease, creating a strong and permanent bond. LIGNOLOC® is the most sustainable professional fastening system currently available. It reduces CO₂ emissions by 66% compared to conventional systems and contributes to circular construction practices.

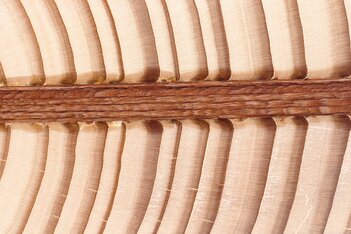

Microscopic image of the connection between the LIGNOLOC® wooden nail and the surrounding wood

High holding force due to LIGNIN Adhesion EFFECT

Did you know? LIGNOLOC® wooden nails impress with their high holding power. Thanks to Lignin Adhesion. Due to the special design of the LIGNOLOC® nail tip and the large amount of heat generated by friction when the nail is driven in, cause the lignin of the wooden nail to fuse with the surrounding wood to form a substance-to-substance joint. Discover now in our video how this impressive effect works.

Approvals

The approval confirms the use of LIGNOLOC® wooden nails for wood-to-wood or panel-to-wood connections. The withdrawal and shear resistance of LIGNOLOC® wooden nails meet the requirements of the ASTM D1761-20 standard for mechanical fasteners in wood.

The ETA approval applies to the LIGNOLOC® wooden nails without head and enables the planning, design, and execution of load-bearing connections in timber frame construction. The provisions made are based on an assumed intended working life of LIGNOLOC® nails of 50 years.

The ETA approval applies to the LIGNOLOC® wooden nails with head and enables the planning, design, and execution of load-bearing connections in timber frame construction. The provisions made are based on an assumed intended working life of the LIGNOLOC® nails of 50 years.

The innovative fastening system LIGNOLOC® not only excites us. The first collated nail made of wood also convinced the expert committee and received the general national technical approval for “load-bearing wooden connections using LIGNOLOC® wooden nails” by the DIBt.

The future of timber construction – our mission

With LIGNOLOC® it is possible to connect wood to wood with wood creating the most natural and ecological connection of all.

Lignoloc® wooden nailing systems

The LIGNOLOC® system opens up many possibilities for you. The nails are available in various diameters and lengths. Since January 2023 brand new also with head perfect for outdoor applications. For the portfolio of nails, there are two handheld tools and two nailing heads for robots or portal CNC machines for stationary applications. Thus, it adapts exactly to your requirements.

lignoloc® applications

The LIGNOLOC® system from BECK opens up countless application options for you – whether it be indoors, outdoors or in areas susceptible to corrosion.

overview applications

-

Timber frame construction

-

Massive timber constructions: LCLT, CLT, NLT

-

Wooden façades

-

Fences

-

Furniture

-

Pallets & crates

-

Sauna

-

Interior wood cladding

-

Floors: OSB- and real wood flooring

-

Boats

-

Working with reclaimed wood

-

CNC applications (prototypes)

-

Wooden coffins

-

and many more

Lignoloc® in massive timber construction

LIGNOLOC® wooden nails can be used in various ways in the production of multilayer solid wooden boards. Depending on the manufacturing process, they are used for fixing the layers temporarily or as a replacement for aluminum nails and wooden dowels, or else they give a rise to entirely new processing methods. This means time-related advantages and ecological benefits for the industry.

selected LIGNOLOC® references

With LIGNOLOC® we have developed a new, groundbreaking product whose idea and unique properties are inspiring. LIGNOLOC® has already won many awards, such as the German Design Award for innovative product design. We celebrate every award, but we are even more enthusiastic about the implemented projects and the success of our customers with LIGNOLOC® - because that's what it's all about.

"As an innovative craftsman's business, we are always open to new things. We installed the wooden facade of our new factory hall with LIGNOLOC® and are thrilled. We will also recommend the LIGNOLOC® system to our customers."

FAQ

Depending on the nail dimension and the metal fastener to be compared, CO2 emissions can be up to 75 % lower.

The plastic sheet is state of the art and provides the opportunity of processing LIGNOLOC® wooden nails without leaving any residue or waste. The plastic sheet can easily be recycled.

It all depends on the density of the wood. As described in Eurocode 5, table 8.2, attention must be paid to the density of the wood type when fastening wood using pin-shaped connectors. Only woods with a density less than 500 kg/m³ may be nailed without pre-drilling.

Yes. We recommend use of the FASCO® F44 LIGNOLOC® by BECK, a tool designed specifically to meet the requirements of the wooden nail. The larger opening in the feed mechanism and the guide flaps are important for a perfect shooting result.

BECK offers a specialized setting tool in its FASCO® tool line for processing the LIGNOLOC® wooden nail with head. This tool has been optimized for error-free processing of the nails. Older models of the FASCO® F60 series can be adapted for the processing of the LIGNOLOC® with head with a conversion kit from FASCO®.

In rare cases, slight splintering of the nail head may happen. These splinters do not affect the durability of the nail.

The FASCO® F60 nailer should be set by adjusting the air pressure and depth of the tool and by performing test shots on an inconspicuous area of the façade or on a mockup of the materials used. If this setting is maintained and the user applies uniform pressure to the façade, a uniform driving depth can be achieved. Large variations in wood density within the materials to be applied can lead to fluctuations which must be compensated for by readjustment.

BECK's LIGNOLOC® wooden nails with head can be used as a substitute for façade screws. Horizontal and vertical cladding made of softwood can be fastened to wooden substructures with LIGNOLOC®.