Mass Timber Construction with LIGNOLOC® Wooden Nails

Circular construction without glue and metal

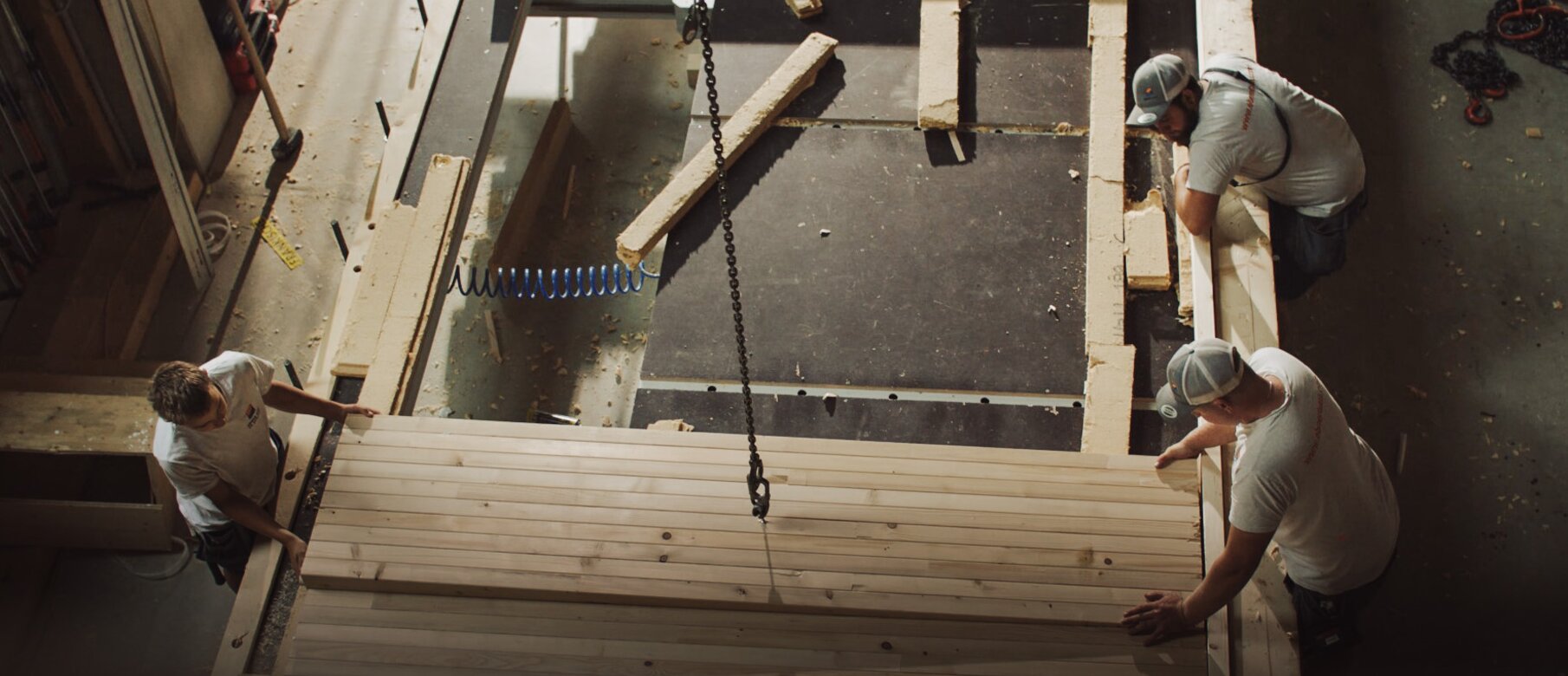

With LIGNOLOC® Wooden Nails, architects, planners, and timber construction companies can rely on an environmentally friendly, efficient, and aesthetically appealing alternative to traditional fastening methods in mass timber construction. Made from European beechwood, they offer significant advantages: compared to steel nails, they reduce CO₂ emissions by up to 66%. Thermal bridges are eliminated, and corrosion is prevented. The pneumatic insertion method of the nails not only accelerates the assembly process but eliminates the need for pre-drilling as well. Thus, the LIGNOLOC® system is ideal for the production of cross-laminated timber (CLT) panels and wooden construction modules. CLT elements are upgraded to LCLT (LIGNOLOC® Cross-Laminated Timber) with the innovative wooden nail system from BECK.

When building with LIGNOLOC®, everyone benefits: timber builders, craftsmen, the residents of the buildings – and of course, our environment.

LIGNOLOC® Wooden Nails are protected by patents and have building approvals for the entire EU and USA, as well as an EPD: The high safety and performance of this fastening method are thus confirmed.

‟The highlight of our product is its sustainability. Working with pure wood has always been a major focus in timber construction. The aim is to connect wood with wood. This perfectly reflects the spirit of our times.”

Combined benefits: Wooden nails in mass timber construction

In mass timber construction, load-bearing components such as walls, ceilings, and roofs are made from solid wood. Compared to traditional timber frame construction, this building method offers a number of advantages. Interiors in mass timber construction impress with their aesthetic quality. The visible wood radiates a warm and natural atmosphere, which can positively impact the well-being of people inhabiting the space. Wooden nails, as an innovative fastening method, significantly expand the possibilities of mass timber construction.

Mini-glossary

-

What is Nail-Laminated Timber (NLT)?

Nail-Laminated Timber (NLT) is a building material made of stacked wood boards that are connected by nails. The boards are aligned parallel to each other.

-

What is Cross-Laminated Timber (CLT)?

-

What is LIGNOLOC® Cross-Laminated Timber (LCLT)?

The ecological benefits are clear: LIGNOLOC® Wooden Nails and LIGNOLOC® CLT (LCLT) represent an environmentally friendly construction method.

‟Flexibility, aesthetics, and sustainability: In solid timber construction, LIGNOLOC® wooden nails do not only offer technical and ecological advantages but open up entirely new possibilities in architecture and interior design.”